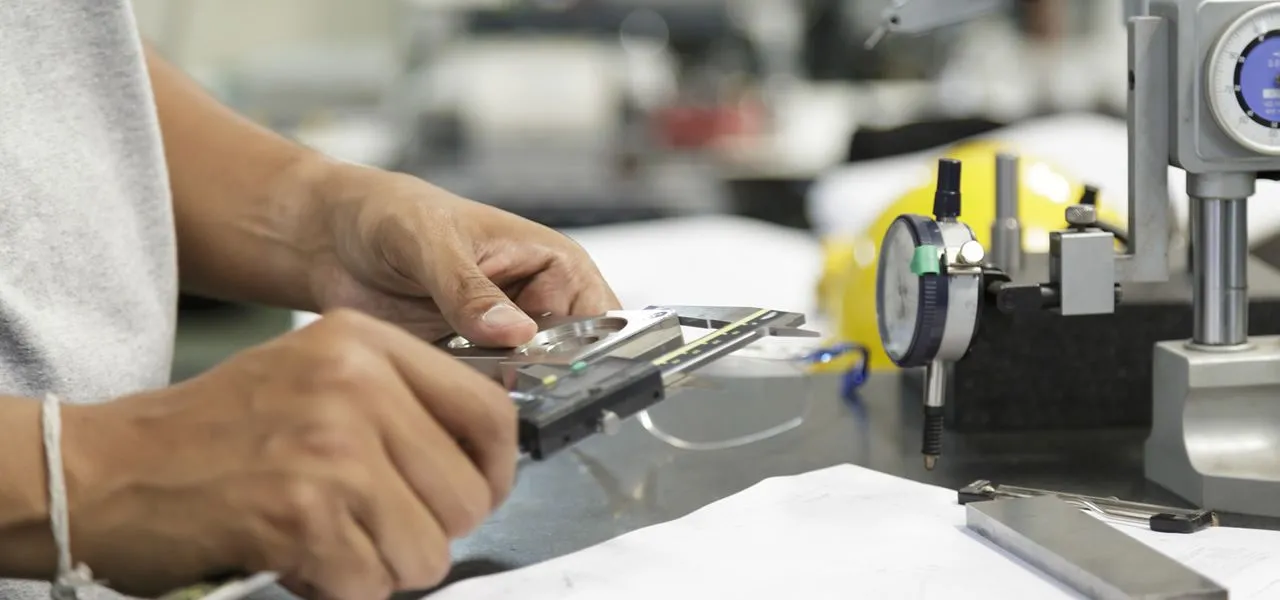

At Hogan Technical Solutions, we understand that the accuracy of your CNC machines directly impacts the quality of your output. Our expert calibration services ensure your machines maintain the highest levels of precision, resulting in superior product quality, reduced waste, and increased productivity.

We utilize state-of-the-art tools and methods:

Fine-tuning of:

Verification of:

We meticulously check and adjust:

Implementation of:

We have expertise in calibrating machines from all major manufacturers, including:

Our CNC Machine Calibration Services cater to various sectors, including:

We provide expert CNC calibration services throughout Central and Southeast Texas, including:

Don't let inaccuracies compromise your product quality. Invest in the precision of your CNC machines with Hogan Technical Solutions' expert calibration services.

We prioritize emergency calls and dispatch technicians as quickly as possible to minimize downtime.

We service CNC lathes, mills, routers, and multi-axis machines.

Yes, we provide detailed diagnostics and transparent quotes before proceeding with repairs.

Yes, our work is guaranteed to meet or exceed OEM specifications.

Our Services

Get In Touch

Phone Number

512-630-6325

Email Us Here

Office Address

College Station, Texas 77842

About Company

At Hogan Technical Solutions, we keep your CNC machines running at their best. From emergency repairs to preventive maintenance, we’re your trusted partner for all things CNC in Central and Southeast Texas.

Useful Links

Services

© 2025 Hogan Solutions. All Right Reserved.

Your CNC Machine Experts

At Hogan Technical Solutions, we keep your CNC machines running at their best. From emergency repairs to preventive maintenance, we’re your trusted partner for all things CNC in Central and Southeast Texas.